Hello! Today, we're delving into the exciting world of Continuous Fiber Reinforced Thermoplastic...

Covestro pioneers an innovative venture in polycarbonate (PC) recycling

Covestro is currently conducting a groundbreaking chemolysis experiment at its Leverkusen facility in Germany. This innovative process is specifically designed to recycle polycarbonate (PC), revolutionizing the way plastic waste is managed. The plastic waste undergoes a transformative process, where it is converted into monomers and seamlessly reintroduced into the polycarbonate production process.

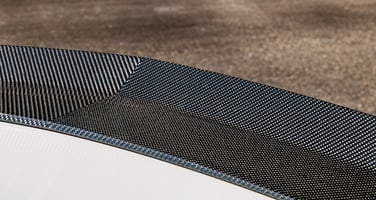

Covestro highlights that the resulting PC material from depolymerisation can be effectively mass-balanced and utilized as recycled material in demanding applications, eliminating the need for further processing. These raw materials are particularly sought-after in industries like automotive, where safety, optical transparency, and aesthetics are of utmost importance.

This innovative chemolysis process has proven successful in recycling pre-sorted waste streams that contain over 50% polycarbonate (PC). By utilizing this method, various plastic waste streams containing polycarbonate have been transformed into a direct precursor of PC, effectively closing the recycling cycle. Not only does this approach make the recycling process highly sustainable, but it also ensures that valuable materials are not wasted.

After achieving success in the laboratory, Covestro has already commenced the next phase of implementing a continuous process. To gather the necessary data for further expansion, they are currently in the planning stage of a pilot plant. This exciting development promises to bring even more advancements to their groundbreaking chemolysis experiment in recycling polycarbonate.